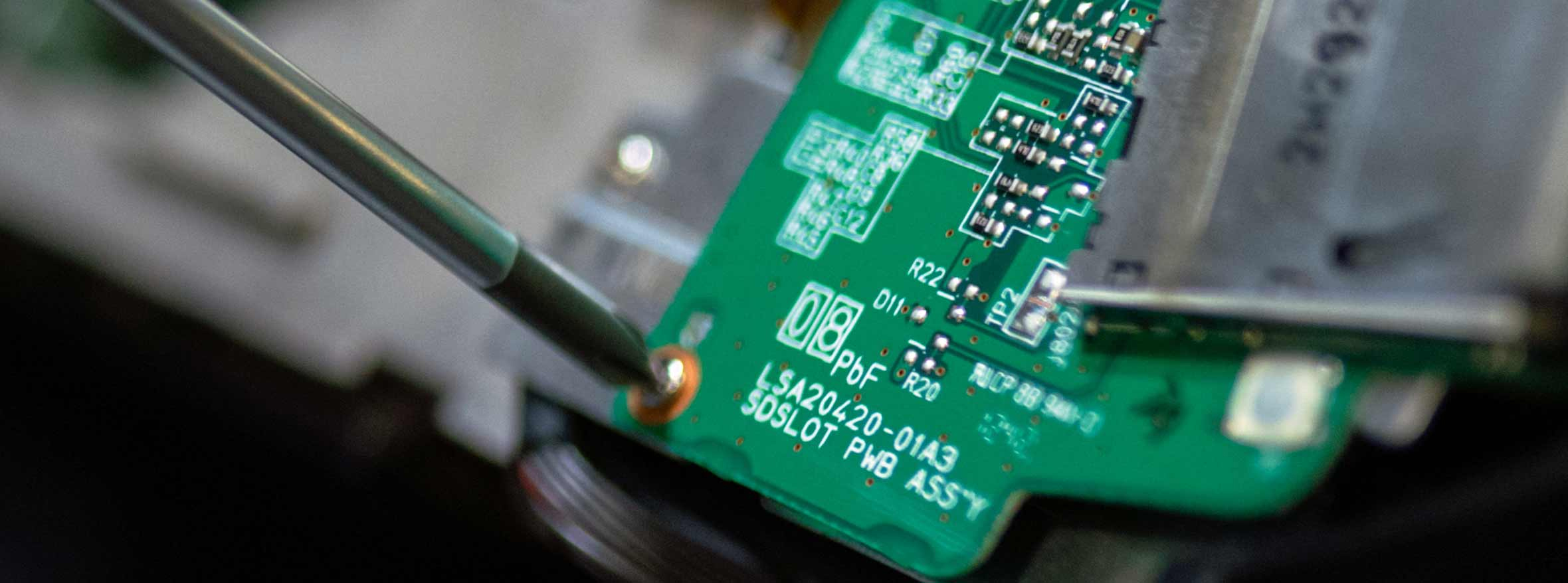

In recent years, Automated X-ray inspection (AXI) is a technology based on the same principles as automated optical inspection (AOI). It uses X-rays as its source, instead of visible light, to automatically inspect features, which are typically hidden from view.

As BGA connections are not visible the only alternative is to use a low level X-ray inspection. AXI is able to find faults such as opens, shorts, insufficient solder, excessive solder, missing electrical parts, and mis-aligned components. Defects are detected and repaired within short debug time.

The image is processed by image processing software that detects the position and size/ shape of expected features or presence/ absence of unexpected/ unintended objects or features . Instead of visible light it uses x-rays that pass through the object. Opposite the x-ray emitter is a detector that either converts x-ray into visible light (creating an optical image which is then picked up by a camera) or sensor arrays that directly pick up the x-ray and convert it into an electronic image. The image is produced due to the different absorption of x-rays when passing through the object and can, therefore, reveal structures inside the object that are hidden from outside view.

Our Contacts

- Sector 63,Noida, Uttar Pradesh

- +91 70603 08061